Exe Single Compression Unarmoured Cable Gland - IECEx ATEX Hazardous Area

Exe Single Compression Unarmoured Cable Gland - IECEx ATEX Hazardous Area

Couldn't load pickup availability

SH-BDM-1 series of Ex Hazardous Area Explosion Proof Cable Glands; is used for non armoured elastomer and plastic insulated cables for indoor and outdoor use in Hazardous Areas of Explosive Atmospheres. This cable gland may also be used with braided cables where the braid and outer sheath pass into the enclosure.

Sealing Material: Silicone Rubber, Neoprene, Teflon, PA6

Standard Accessories: Nylon Washer, Lock Nut (Besides NPT Thread)

Accessory Bundle Kit: Earth Tag, PVC Shroud, Serrated Washer, Red Fibre Washer, AB Putty Compound.

SKU: SH-BDM-1

Collapsible content

Technical Datasheet

Shipping

Manufacturing lead time is dependant on quantity ordered. This is excluding the delivery lead time which is estimated at checkout.

We aim to process and get your delivery with you as quick as possible.

Please contact us to retrieve the estimate lead times for your order.

Guarantee

We aim to provide you with the best quality products, if for an unfortunate product defect we have a 14 day money back return guarantee.

Warranty

• 1 year warranty from the date of purchase.

• Invoice or shipment bill is required to claim the warranty.

• The warranty policy only requires manufacturer to repair the defective product or send substitute for replacement.

• Installation labour, electricity cost and other related cost will not be covered by the manufacturer warranty policy.

• Warranty doesn't cover the defect caused by inappropriate use, especially if directions of the instructions for use are not observed, normal abrasion as well as failures which affect the value or use of the product insignificantly.

Please see our returns policy for more information.

-

Hazardous Area Certified

Certification

- IECEx

- ATEX

Zone Location

Ex eb IIC Gb

Ex tb IIIC Db

-

Features & Inclusions

SEALING MATERIAL: Silicone rubber, Neoprene, Teflon, PA6.

FIREPROOF GRADE: VO (UL94)

Ex EPL: Increased safety, dust-proof.

STANDARD ACCESSORIES: Nylon washer, Lock nut (besides NPT thread)

OPTIONAL EXTRAS: Earth tag, PVC shroud, serrated washer, red fibre washer, AB putty compound

Advantages

-

Corrosion Resistance

Our explosion proof cable glands are designed to combat the effects of explosive gases and dusts, with acid, alkali, strong corrosive gas, or water vapour.

-

Impact Resistant

Our explosion proof cable glands are designed and tested to combat the effects of drop and impact bump to the gland.

-

Pull-out Resistant

Our explosion proof cable glands are designed and tested to combat the effects of strain to the cable that may pull on the cable from the gland.

Manufacturing Process

- Cutting-cut the metal bar

- CNC machining

- Thread machining

- Deburring

- Electroplating

- Assembly

- Engraving

- Conformity check

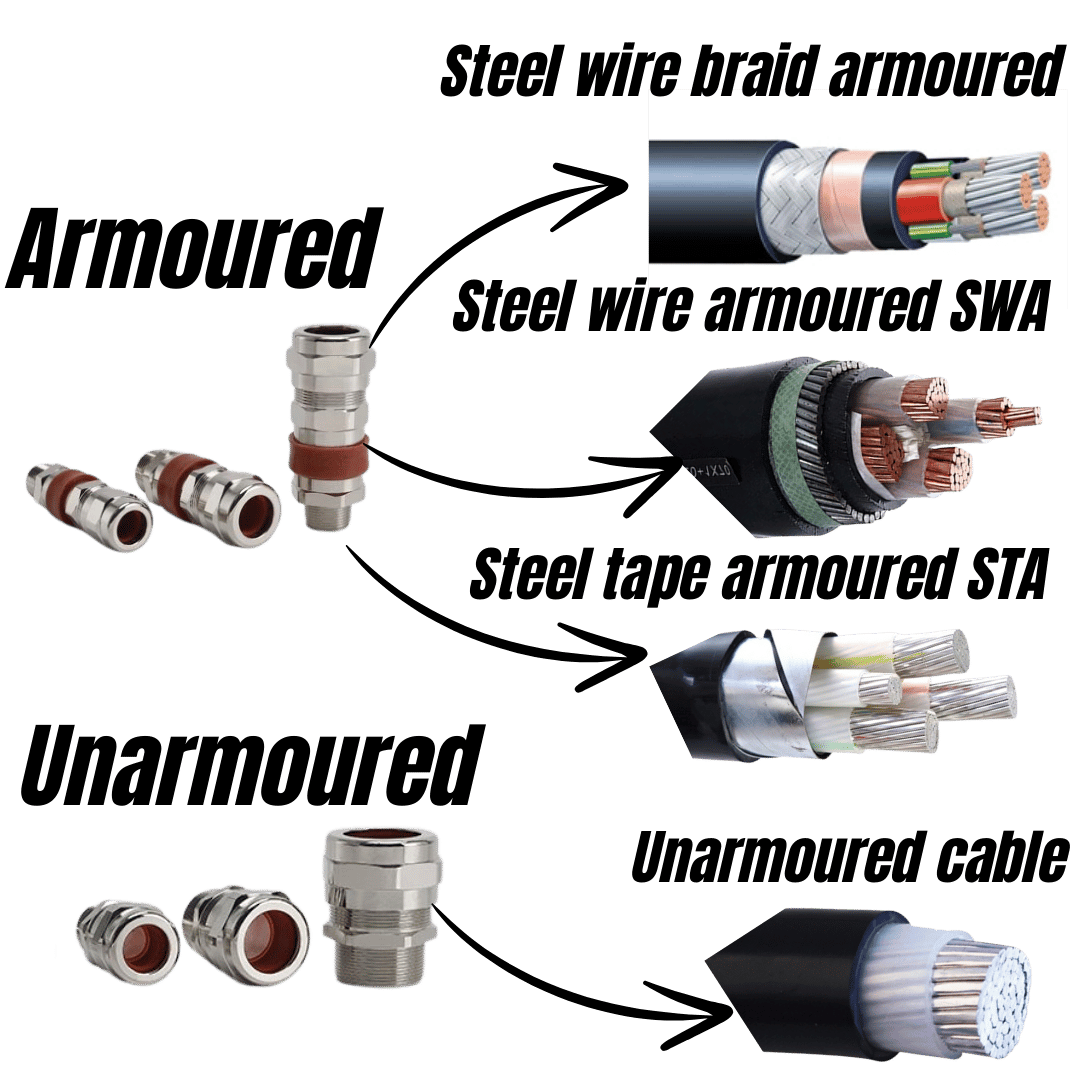

- For use with armoured cable such as steel wire, steel braid, steel tape, elastomer and plastic insulated.

- For use with unarmoured cable.

Helpful Information

-

Cable sealing options for different flameproof equipment

For Ex cable glands there are two types of sealing

- Ring Seal

- Packing + Sealing Ring Seal

Although the single sealing ring can play a role in explosion proofing. The sealing ring has a fixed shape and can be sealed by extrusion, not 100% air tight. For packing seal, the cable can be completely wrapped by the putty compound. Which can better achieve a sealing flameproof effect.

-

For explosion proof cable glands, the protection method must meet or exceed the protection level of the equipment that is connected to the cable gland.

Exd enclosures or equipment must be equipped with Exd cable glands. Exe or Ext only cable glands cannot be used with Exd equipment. However Exd cable glands can be used on Exe device or housings.

-

When to use a barrier gland - Exd

A Barrier gland MUST be used in an Ex d environment

unless the cables:-

Are circular and compact

Have an extruded bedding or sheath

Use non-hygroscopic fillers. -

When to use a barrier gland – Ex e / Ex nR

Barrier glands should also be used:-

• In Ex e applications when there is a risk of gas

migrating down a cable.

(IEC Ex 60079-14 clause 9.3.2)

• In Ex nR applications where the cable is not sealed.

(IEC Ex 60079-14 clause 10.8)

Cable Gland Manufacturing

CAPABILITIES

- M thread size from M8-M120, thread pitches x1,x1.5,2,3

- NPT thread size from NPT1/4" to NPT5

- G thread size from G1/4" to G5

- PG thread size from PG7 to PG63

- PT and PF thread sizes.

Hazardous Area Cable Glands Manufacturer

Production factory covering 2000m2, working to accommodate the demand of the industrial industry needs. Holding more than 10,000 in stock finished cable glands.

Cable Gland Selector Tool

-

Pre & Post After Sales Support

After Sales Support

We offer after sales support on all our products including

- Installation

- Configuration

- Maintenance

- Repair

- Calibration

-

Engineering Design & Fabrication

Contact us- CAD drawing.

- P&ID.

- Component selection.

- Bill of materials.

- Factory Acceptance Testing (FAT)

- Professional packaging and delivery.

Our Core Values

-

UNPARALLELED SUCCESS

We embrace every challenge as a team with our expertise, and have a proven track record of success when we collaborate.

-

WORK SMARTER NOT HARDER

In order to do great work, we need knowledgeable, well-trained individuals, combined with automation. We are dedicated to not only providing our team with top-notch training, but also world-class equipment to ensure we’re stay at the cutting edge of the industry.

-

TAKE PRIDE

Since the beginning, we have always believed in the quality and longevity of the products we sell and service we provide, and are proud to offer our expertise to all industries.