Options

-

Wire Mesh Cable Tray

-

Fibre Cable Tray

-

Porous U-Type Cable Ladder

-

Cable Trunking

-

Perforated Cable Tray

-

Cable Ladder

-

Seismic Bracing

-

Certified and Compliant

Products obtain CE,UL,CUL certification. With perfect qualification certification and strong research and development capabilities, it has more than 57 invention patents and 58 trademark applications around the world.

-

Installation Support

Our team have experience with renew or new installations. Allow us to help you with your project to save time and resources.

Advantages

-

Light Weight

The weight of wire mesh cable trays are 1/5 of traditional cable trays, making

them easier to install. -

Clean & Easy Maintenance

The open design allows continuous airflow, which prevents overheating and

the build-up of dust and contaminants. Cable visibility allows for more convenient upgrading and maintenance. -

Customisable

All kinds of elbows can be made at the project site flexibly. Multiple finishes are available for indoor and outdoor applications.

-

Corrosion Resistance

-

Impact Resistant

-

Pull-out Resistant

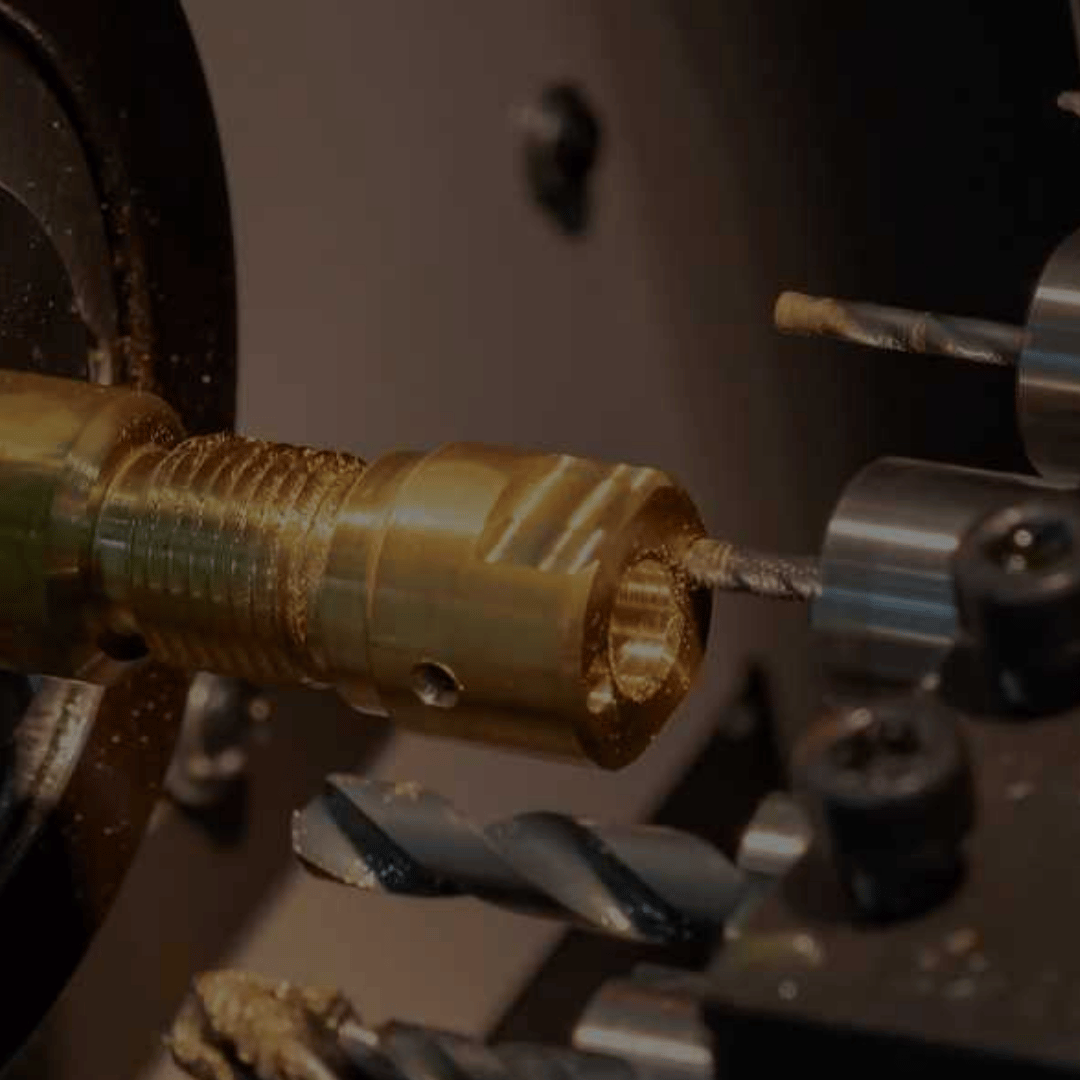

Manufacturing Process

- Cutting-cut the metal bar

- CNC machining

- Thread machining

- Deburring

- Electroplating

- Assembly

- Engraving

- Conformity check

Wire Mesh & Cable Tray Manufacturer

Production factory covering 2000m2, working to accommodate the demand of the industrial industry needs. Holding more than 10,000 in stock finished products.

Case Studies

-

Data Centre - QLD

-

Power Plant - QLD

Materials we offer

-

Electrogalvanized

-

Hot Dip Galvanized

-

Dacromet

-

Pre-Galvanized

-

Powder Coated

-

Nickel Plated

-

Zinc-Nickel Plated

-

SS304

-

SS316

-

SS316L

-

Aluminium

-

PVC

-

ABS

-

Ungalvanized

Contact us to request or Quote or view our Catalogue

AUSTRALIAN OPERATED AND OWNED.

Our Core Values

-

UNPARALLELED SUCCESS

We embrace every challenge as a team with our expertise, and have a proven track record of success when we collaborate.

-

WORK SMARTER NOT HARDER

In order to do great work, we need knowledgeable, well-trained individuals, combined with automation. We are dedicated to not only providing our team with top-notch training, but also world-class equipment to ensure we’re stay at the cutting edge of the industry.

-

TAKE PRIDE

Since the beginning, we have always believed in the quality and longevity of the products we sell and service we provide, and are proud to offer our expertise to all industries.